(PST) develops and manufactures a range of hardware devices for the detection, identification, verification, and measurement of fluids within closed environments. Originally developed by the US government, this patented technology is controlled by the Tucson, Arizona-based company, to introduce innovative products & devices for commercial, government and military applications, including drug enforcement, Health & Safety, theft and fraud detection, as well as for tracking and monitoring material assets.

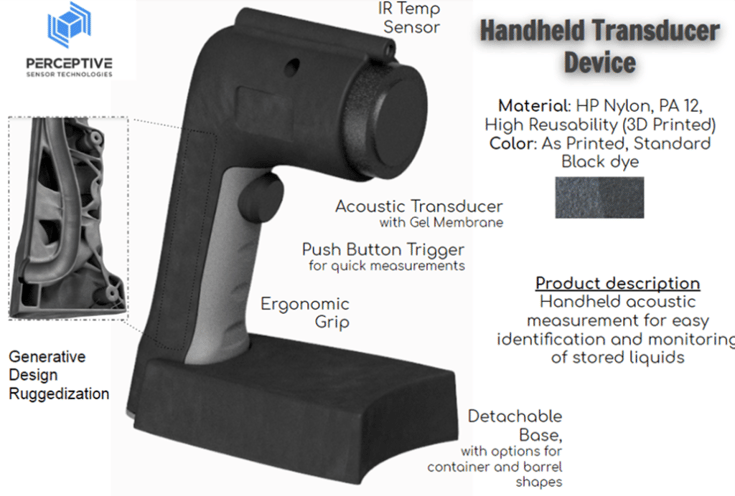

The PST technology is based on some very effective science – at any given temperature, every fluid has an individual acoustic signature, as unique as any human fingerprint. Thus a sound wave travelling through a contained fluid produces a unique, identifiable measurement. PST’s devices are now being used across a range of industries and need to meet high-performance goals for precision, ease of use, and durability in the field. However, as one might imagine, many of the applications for these devices require distinct and adaptable functionality, without compromising the high performance goals.

The requirement, therefore, was to develop a hand-held device that would meet these criteria, while also providing an adaptable solution that allowed for the production of small batch, customized solutions for specific industries.

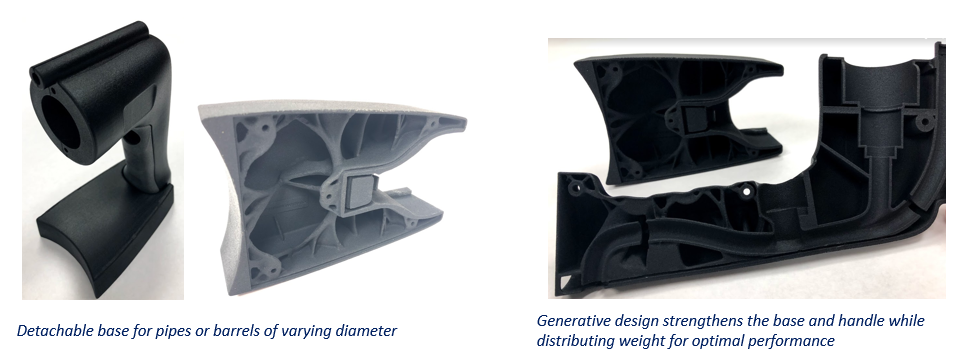

To achieve this goal, PST collaborated with Penumbra, a product development company that specializes in the use of generative design and additive manufacturing (AM) technologies to support hardware companies with the development of innovative and performance driven products. It was a good match, one that resulted in Penumbra developing a detachable device adapter that would allow PST to customize its advanced ultrasonic devices to address the specific needs demanded by potential clients for niche applications and extending the company’s business opportunities considerably. Key to the design of the adapter was durability (enough to withstand some extreme environments) and that it was both lightweight and balanced enough to ensure proper stability as well as being easy to use for the technicians operating it in the field.

With the experience in-house at Penumbra, the solution was rapidly identified through use of the comprehensive generative design capabilities in Autodesk Fusion 360, which allows the designers to input their specific design goals (along with parameters such as materials, manufacturing method, and cost constraints). Subsequently, when run, the software explores all the possible permutations of a solution, quickly generating design alternatives. It tests and learns from each iteration what works and what doesn’t in line with the parameters that have been set.

These capabilities enabled the Penumbra team to quickly explore a large number of design solutions to solve this complex challenge and to run several studies to arrive at an optimal solution that could be produced using additive manufacturing. The use of AM technology, in this case the MultiJet Fusion process from HP with its Nylon PA12 material, allowed for the small series production of these complex parts in an extremely robust material. For this project, the generative design solutions worked with parameters that prioritized minimizing and equally balancing the weight of the device for ease of use and ergonomic benefit while maximizing stiffness to ensure durability.

The results produced by the Penumbra team exceeded expectations and resulted in a new state-of-the-art ultrasonic sensing device that provides the accuracy and durability customers expect and, in addition, the means of production required minimal upfront investment — a further win. Moreover, because of the generative design capabilities within Fusion 360, this device can be further customized to address the niche requirements of new customers, ensuring PST maintains its competitive edge and a platform for continued growth.

“Additive manufacturing and generative design are helping improve product performance for our customers, optimizing the strength, weight, and cost. In this case, the solution we designed will allow PST to scale their business with small batch production, while addressing the needs for niche industry applications.”

Steven Szymeczek

Co-founder, Penumbra