If you are going to connect parts together one time, then designing the threads in the part is a good option. If the parts will be put together and taken apart multiple times, heat-set inserts are the answer.

We recommend using metal heat-set inserts. (We love heat-set inserts!)

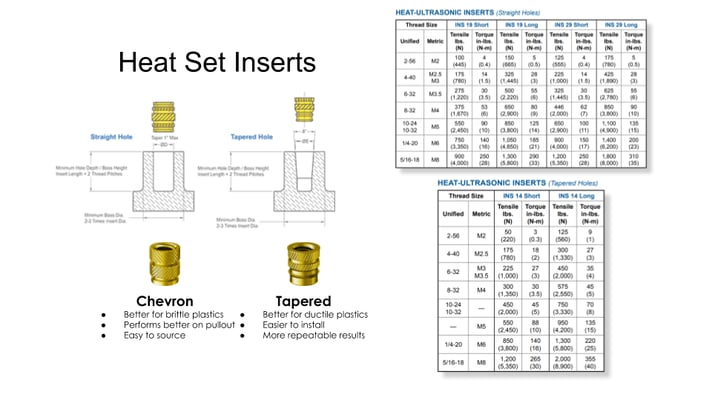

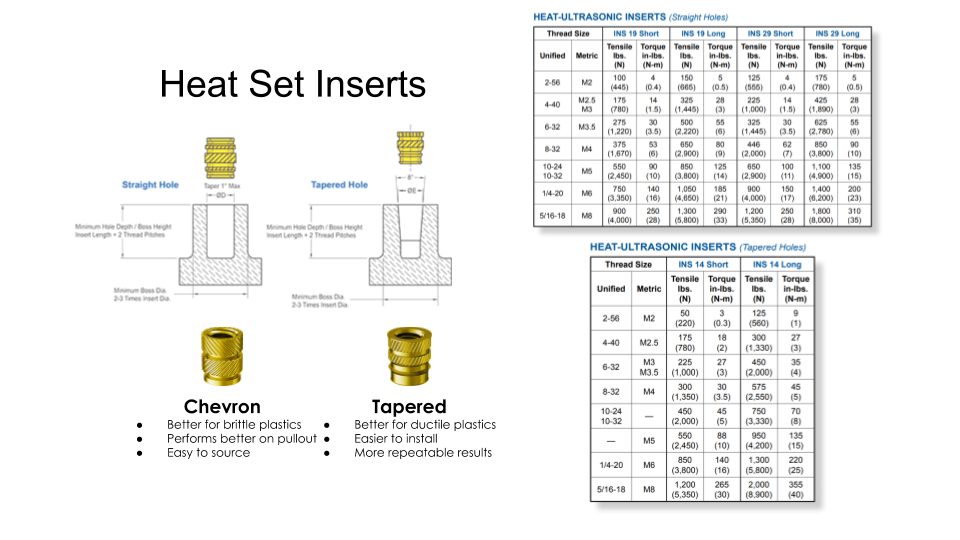

A heat-set insert is a threaded insert made out of metal. It’s heated with a soldering iron and then pressed into a hole in a plastic 3D printed part. The heat from the metal insert melts the surrounding thermoplastic, and as it cools, the material molds around the insert, securing it in place.

Here are the key benefits of using heat-set inserts for your 3D printed parts:

Durability

You could 3D print plastic threads instead of using heat set inserts. But plastic threads wear down quickly, especially if you plan to un-thread and re-thread (think unscrew and re-screw) them repeatedly when using the part.

According to Markforged, “Tapped or printed plastic threads are easy to overload and strip out, while metal threads are stronger and wear resistant, providing a better connection over time.”

A heat-set insert will stand up to reuse, thanks to the durability of the materials used and the bond created in the process.

Pullout and Torque Strength

Heat-set inserts also have a greater pullout strength than 3D printed threads. They resist pull-out and torque-out loads thanks to the external surface features that are designed to work with a larger bulk part and prevent stripping.

The pullout strength of our HP printed parts is already extremely high, and comparable to the strength of an injection-molded part. Using heat-set inserts ensures that pullout strength isn’t compromised whatsoever.

Precision

Precise installation is crucial to guarantee that a locking component will mate perfectly to the heat-set inserted piece. Most heat-set inserts are installed by hand. If the surface is flat and there are only a few parts that need to be made, this isn’t usually an issue.

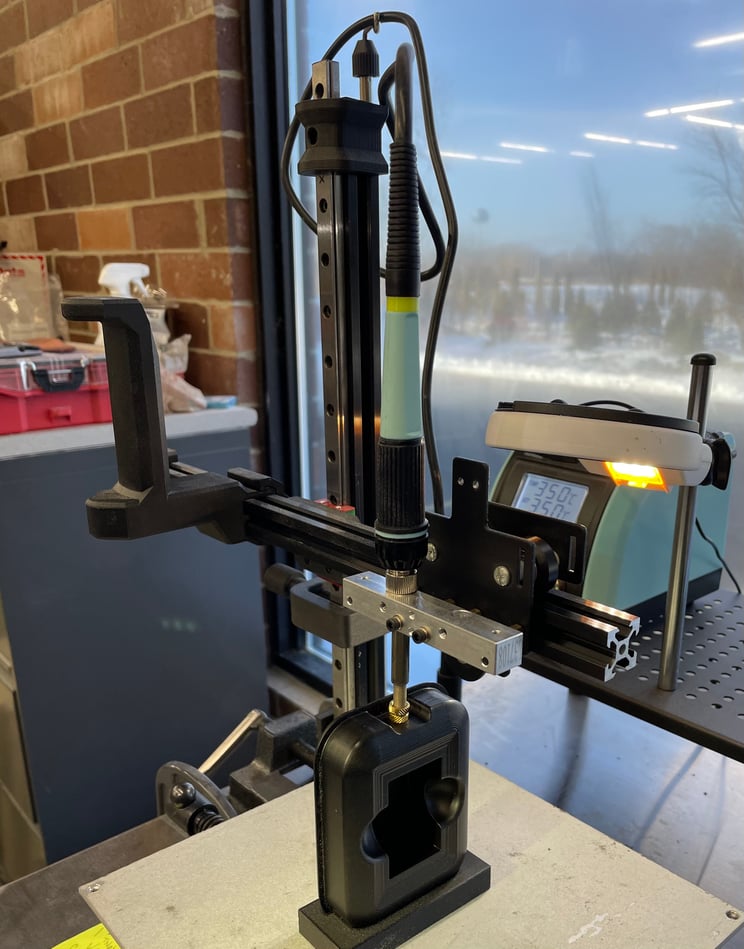

However, manual installation isn’t feasible for additive production at scale. It’s not efficient or even possible to maintain the same level of precision for a high volume of parts. And if parts require a different angle of insertion, manual installation can be tricky to downright impossible.

Re3DTech Does Heat-Set Inserts Better

At Re3DTech, we’ve developed a fully-customized in-house tooling solution for heat-set inserts, allowing us to perform installations consistently, even at the most difficult angles.

This custom tooling avoids issues like tolerance stacking that can affect the functionality of a part and delivers a high-precision installation every single time. It also allows us to efficiently install heat-set inserts at production volumes without relying on manual insertion.

Choosing the Right Heat-Set Insert for Your Part

Engineers can build heat-set inserts right into their design models. We typically work with McMaster-Carr and TriStar for heat-set insert installation.

[Download a guide to designing for heat-set inserts]

Contact us if you have questions about the right heat-set insert for your part. We’re always happy to provide recommendations!

Let Re3DTech install heat-set inserts on your next additive manufacturing project. Request a quote today.

At Re3DTech, we believe that 3D printing will repatriate and revitalize our manufacturing industry – and is the future of American manufacturing! Re3DTech provides 3D printing and contract manufacturing services with a commitment to quality, speed, and customer service. We supply thousands of parts to customers every week in industries including Healthcare, Automotive, and Aerospace. It is our mission to provide a custom solution to our customers’ needs.

Leveraging our production additive manufacturing technologies, we have the in-house expertise and capabilities to help lead your company down the path of additive. Take advantage of the advances in 3D printing to improve your manufacturing - contact us today to see how we can help!