Markforged, a leading provider of metal and carbon fiber 3D printers, has announced Blacksmith, the first Artificial Intelligence (AI)-powered software that makes manufacturing machines ‘aware’ so they can automatically adjust programming to ensure every part is produced as designed. Blacksmith is a breakthrough in smart factories and the first example of Adaptive Manufacturing, which will reduce the cost of production and reshape the industry as we know it.

“For the last hundred years, machines have been unaware of what they’re creating and would happily waste millions of dollars producing out-of-spec parts. We’re going to fix that by connecting the machines that make parts, and the ones that inspect them, with a powerful AI,” said Greg Mark, CEO of Markforged. “Much like the way Tesla is building autopilot for cars, we are building an autopilot for manufacturing.”

Starting with Markforged’s Metal X and X7 3D printers, Blacksmith will create a continuous feedback loop to make 3D printed parts more accurate. The intelligent software massively cuts waste and accelerates time to market. It analyzes a design, compares it to the scanned part, and automatically adapts the end-to-end process to produce perfectly in-spec parts.

“3D printing is just the start — we plan to extend the Blacksmith AI to connect all machines in your factory,” said Mark. “We will enable the first generation of machines that know what they’re supposed to make, and can adjust themselves to produce the right part, every time.”

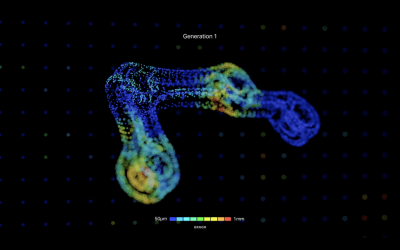

The way Blacksmith works is that a part is scanned each time it is 3D printed. The point cloud data from this scan, as well as process parameters and some CAD information, is automatically fed back to Blacksmith. The technology then compares all the data to determine how the outcome can be made closer to the intended CAD file.

Without such a process, machines are blind to the objects they are making. Rather than carrying any specifics about a part though, the platform is more interested in the fundamentals of a design, e.g. the optimal conditions for creating bridges in a 3D printed part, or how to create features of a certain size. In this sense Blacksmith’s intelligence, according to Mark, can be likened to the way Tesla “teaches” its cars to drive.

“They don’t care how you or I drive visually, they’re just learning how to drive,” he explains. “AI is learning how to drive. AI is learning how manufacturing works. How sintering works. How CNC machining works. How 3D printing works.”

The more data Blacksmith is given, the tighter the tolerances it will get when producing parts. In 3D printing, Markforged is currently producing tolerances comparable to casting. The pursuit of the Blacksmith platform is to get as close to the digital CAD file as possible.

Blacksmith will be particularly powerful for the new generation of metal 3D printing. The latest breakthrough methods all require sintering — a process that notoriously distorts parts. Blacksmith will eliminate this challenge and deliver precise parts post-sintering.

Blacksmith will be available later this year.