The standard output, whether it’s for aerospace 3D printing, industrial 3D printing, or any other 3D printing service, is a dull, unfinished gray or black color. While a plain-looking part is usually perfectly fine for internal components, external components need post-processing in order to look their best.

At Re3DTech, we’re committed to producing high-quality parts that have an aesthetically pleasing, finished look. Therefore, we automatically include a full range of post-processing services with your order to improve the part quality and deliver a consistent, cosmetically-enhanced appearance.

We’re able to offer these services thanks to our investments in automated, mechanical systems designed for production volumes. This results in a lower cost for post-processing and eliminates the guesswork of time-consuming, manual labor.

Here’s an overview of the intensive post-processing your parts go through when you work with Re3DTech:

Phase 1: Cleaning 3D Printed Parts

Cleaning is the first step in post-processing, and its purpose is to remove any and all powder from crevices and surfaces in the freshly printed parts. You want your parts as clean as possible to ensure color consistency during the dyeing phase. Many businesses use manual bead blasting for cleaning, but this approach typically doesn’t remove all of the powder from the part’s crevices and holes, which can result in stains and discoloration when it’s dyed.After printing, our parts will be transferred to the DyeMansion Powershot C, which cleans the parts consistently. This automated tumbler was built specifically for additive manufacturing to de-powder parts quickly and effectively.

The DyeMansion Powershot C uses two simultaneously blasting nozzles to remove any excess powder and clean the part’s surface. The automated machine uses the same air pressure, distance, and time to ensure every batch of parts gets the same treatment. The amount of time it takes to clean the parts is also highly predictable, helping us to adhere to quoted lead times.

Repeatability in process is extremely important for 3D printing services at production volumes. The ability to de-powder a part mechanically, without human variability, makes post-processing viable for producing 3D printed parts at scale.

Phase 2: Dyeing 3D Printed Parts

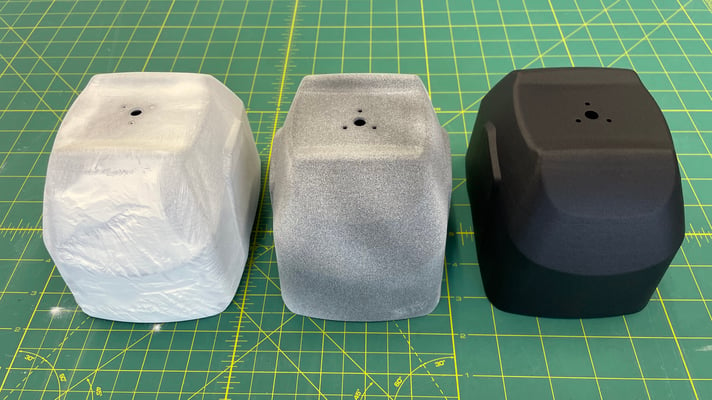

When we print parts on our HP 3D printers, the parts all come out the same color: a plain, gunmetal gray (unless you’re using HP for 3D color printing). The matte finish gives the parts a dull appearance; on their own, they don’t pop or deliver that wow factor our customers are looking for.That’s why the second phase of post-processing is dyeing the parts. We typically dye 90% of the parts black, although other colors are available. It can be tricky to dye parts that are consistently the same color every time which is important for production end-use parts.

After thorough investigation of the options, we chose to partner with Omegasonics for our dye station. In fact, Re3DTech is the beta site for the Omegasonics dye tank, making us the only facility in the world with both HP 3D printing and Omegasonics dyeing capabilities.

- Our semi-automated dye station:

- maintains consistent water temperature

- controls water flow (pressure)

- continuously rotates parts so they dye evenly

Phase 3: Shot Peen

After the parts have been dyed, they still have a dull matte finish. The parts are now ready for our DyeMansion Powershot S for further finishing.This second piece of DyeMansion equipment:

- lightly shot peens the surface of the part

- removes any residual stains from the dye process (such as water stains)

- shines up the part

Phase 4: Vapor Smoothing (Optional)

Vapor smoothing takes post-processing one step further to create a beautiful finish on the parts. This final phase is completely optional and is the only service not included in our post-processing suite. The cost for vapor smoothing is based on part size and order volume.

We made another big investment in the AMT PostPro3D in order to offer vapor smoothing. Vapor smoothing gives parts a glossy, almost glasslike finish for your 3D parts: helping them attain that shiny, injection-molded look.

Aside from the aesthetic benefits, vapor smoothing also improves the quality of your parts. It seals the surface and strengthens the parts, making them completely washable and resistant to moisture absorption.

Remember, if you’re designing an external part, the finish is the key. Adding vapor smoothing to Re3DTech’s standard post-processing will give your parts the darkest, blackest, most consistent color available.

Take advantage of Re3DTech’s full post-processing services to make your 3D printed parts even better. Contact us today to get a quote.

At Re3DTech, we believe that 3D printing will repatriate and revitalize our manufacturing industry – and is the future of American manufacturing! Re3DTech provides 3D printing and contract manufacturing services with a commitment to quality, speed, and customer service. We supply thousands of parts to customers every week in industries including Healthcare, Automotive, and Aerospace. It is our mission to provide a custom solution to our customers’ needs.

Leveraging our production additive manufacturing technologies, we have the in-house expertise and capabilities to help lead your company down the path of additive. Take advantage of the advances in 3D printing to improve your manufacturing - contact us today to see how we can help!