Machining has historically been the most reliable source for copper parts which drastically limited the design freedom for engineers. With the new material from Markforged now available, designers are not limited by traditional DfM (Design for Manufacturing) considerations.

Want the inside scoop on this cutting-edge technology? Let’s break it down.

Benefits of Using Copper in Manufacturing

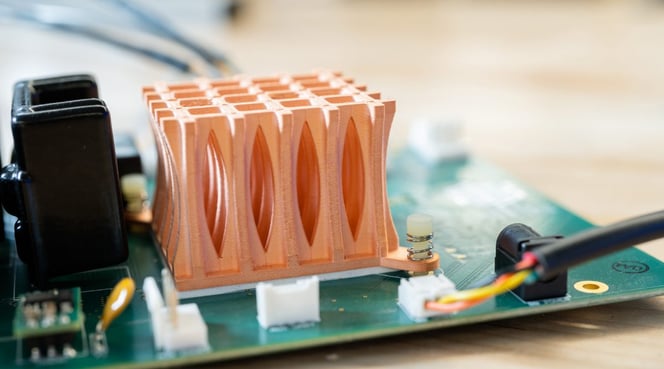

The Markforged Copper is ideal for unique applications that require complex geometries like heat sinks for electronic components and busbars for electrical connectors. With the ever increasing demand for high performance computers, these applications span multiple industries that include aerospace, automotive, oil and gas, automation, and consumer electronics sectors.

Here’s what makes copper the perfect choice for these applications:

- High Thermal Conductivity. Copper is widely regarded by engineers as one of the best materials for heat transfer and conformal cooling applications.

- Lightweight & Malleable. In industries like aerospace where every ounce matters, a lightweight metal like copper can give engineers versatility when designing their part to eliminate excess material mass.

- Excellent Electrical Conductivity. There is a growing demand for custom electronics which requires quick turn solutions for connecting multiple hardware components. The Markforged Copper has proven 3rd party testing data showing it is an excellent choice for custom electronic solutions.

Keep in mind that not all copper is created equal. Different factors during the processing of the raw material can impact elements like thermal and electrical conductivity, so it’s important to use reliable supply chain sources. That is why we choose to utilize Markforged products because when it comes to quality and reliability, they have proven to be one of the industry leaders.

Why 3D Print Copper Parts?

While it’s certainly possible to machine copper, there are specific advantages to choosing 3D printing services for copper parts:

- Design Freedom. Have you ever felt like traditional manufacturing restrictions hinder creativity and innovation? With additive technology, you can add complexity to a part without driving up cost. Minimizing weight in that heat sink you’re designing just got so much easier!

- Internal Features. Need to run a conformal cooling through the interior of a complex 3D part? It is now possible to 3D print conformal channels directly into the interior of your part to boost performance. The limitations of machining no longer have to be the driving factor behind your design.

- Optimized Cooling Capabilities. Additive manufacturing allows for unique part complexity to optimize the surface area of a part, which directly improves part performance and cooling potential.

Comparing 3D Printed Copper to Machined Copper

There’s a common misconception that 3D printed copper isn’t comparable to machined copper, but extensive testing by Markforged shows it can be used directly in existing applications without any concern. Take a look at this data sheet from Markforged.

If you’re interested in 3D printing services for your next copper part, the talented team at Re3DTech is here to help. Request a quote today and we’ll respond within 24 hours!

At Re3DTech, we believe that 3D printing will repatriate and revitalize our manufacturing industry – and is the future of American manufacturing! Re3DTech provides 3D printing and contract manufacturing services with a commitment to quality, speed, and customer service. We supply thousands of parts to customers every week in industries including Healthcare, Automotive, and Aerospace. It is our mission to provide a custom solution to our customers’ needs.

Leveraging our production additive manufacturing technologies, we have the in-house expertise and capabilities to help lead your company down the path of additive. Take advantage of the advances in 3D printing to improve your manufacturing - contact us today to see how we can help!