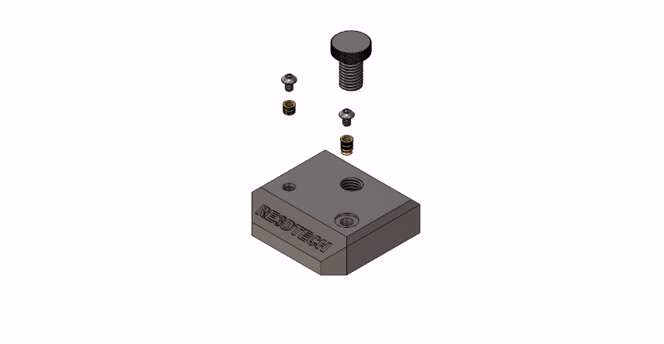

We’ve already documented why heat-set inserts are a better alternative to 3D printed plastic threads:

- They’re more durable because of the materials used and the bond created in the process

- They have greater pullout and torque strength due to the external surface features that are designed to work with a larger bulk part and prevent stripping

- They’re extremely precise thanks to our fully-customized, in-house tooling solution that eliminates the need for manual insertion

But now that you know the benefits of heat-set inserts, you may still be wondering how to go about designing them into your CAD model. Fortunately, there’s not a whole lot you need to remember because it all boils down to one very important factor: providing the part number for your heat-set insert.

Why Provide Part Numbers for Heat-Set Inserts?

Re3DTech is dedicated to automating our processes as much as possible to cut costs and lead times for our customers. Through our Paperless Parts quoting software, we’re able to streamline quoting and get to work on your parts faster than ever before.One of the highlights of our quoting platform is that it allows us to automatically identify part numbers for heat-set inserts and speed up the quoting process. Of course, that means we first need the part number!

Here’s how it works:

- Step 1: You label the heat-set inserts right in your CAD model. We recommend referring to the McMaster-Carr website when selecting your heat-set inserts, as we primarily work with them for heat-set insert installation.

- Step 2: You upload your design file to our website using our secure form.

- Step 3: Our automated quoting software identifies the part numbers for your heat-set inserts and applies pricing based on insertion time and insertion piece price.

- Step 4: We save time, you save time. Everyone wins!

As you can imagine, providing part numbers for heat-set inserts is especially important when dealing with subassemblies.

We recently received a quote for a 25-part project with varying quantity breakdowns. If the customer hadn’t provided the part numbers for the heat-set inserts, it would’ve taken us hours to go through the design and manually enter that information. But because they included that information up front, we were able to respond to their quote much faster and get started on their project right away.

We carry the most popular McMaster-Carr heat-set inserts in-house for even quicker turnaround. But if you need a more obscure insert, we can often get same-day shipping for ultimate speed and convenience.

Now that you know why and how to build heat-set inserts into your part, go ahead and submit your design. We’re waiting to provide you with world class 3D printing services!

At Re3DTech, we believe that 3D printing will repatriate and revitalize our manufacturing industry – and is the future of American manufacturing! Re3DTech provides 3D printing and contract manufacturing services with a commitment to quality, speed, and customer service. We supply thousands of parts to customers every week in industries including Healthcare, Automotive, and Aerospace. It is our mission to provide a custom solution to our customers’ needs.

Leveraging our production additive manufacturing technologies, we have the in-house expertise and capabilities to help lead your company down the path of additive. Take advantage of the advances in 3D printing to improve your manufacturing - contact us today to see how we can help!