Design forAdditive Manufacturing (DFAM) has many advantages over designing for CNC machining, including opportunities for complex geometries, cost-effective iteration, weight reduction, and more.

Design forAdditive Manufacturing (DFAM) has many advantages over designing for CNC machining, including opportunities for complex geometries, cost-effective iteration, weight reduction, and more.

At RE3DTECH, we rely on our design and engineering expertise combined with our comprehensive 3D printing technology to make customers the parts they need quickly and easily. One of the most innovative and exciting tools we use to optimize DFAM is our generative design software.

What Is Generative Design?

Generative design is a design exploration process that models alternative designs to align with part requirements, such as material, strength, dimensions, weight reduction, and cost reduction.

The software uses the predetermined variables to calculate a multitude of different iterations that meet the end-use criteria. The goal of the process is to produce an ideal part.

How Generative Design Mimics Nature’s Evolutionary Process

One way to think about generative design is as a simulated evolutionary process. In traditional evolution, mutations occur constantly, and the successful mutations are passed on from one generation to the next.

%20(1).jpeg?width=233&name=photo-1557612996-198ba8797f5b%20(1)%20(1).jpeg) Generative design works similarly, rapidly altering a design and using any successful optimizations as the basis for the next round of iterations.

Generative design works similarly, rapidly altering a design and using any successful optimizations as the basis for the next round of iterations.

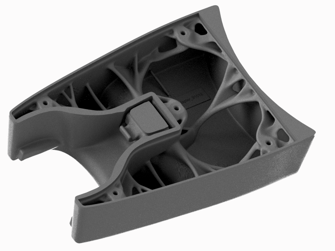

Because generative design and biological evolution rely on similar principles, the designs generated by our software take on an organic, natural appearance. This concept of mimicking natural design is known as biomimicry.

Biomimicry is the reason most generative-designed shapes have a distinctly skeletal appearance, complete with bizarre geometries that CNC machining could never achieve. Additive manufacturing, on the other hand, is perfectly suited for these complex features.

Shapes lacking hard edges and sharp lines are in some ways far ahead of their time. People tend to associate strength and durability with hard lines and sharp edges, so they’re hesitant to accept these skeletal shapes as they are.

When we meet this kind of resistance, we like to remind people that there are no sharp edges on a human skeleton—the result of millions of years of evolution. Generative design essentially accelerates evolution by way of simulation. Still, additional changes are often required to give these parts a more standard and palatable appearance.

The Generative Design Process at RE3DTECH

At RE3DTECH, we leverage our generative design software when we need to achieve certain requirements (material, weight reduction, strength, cost reduction, time to part) for high-risk parts.

For example, we were recently facing an 8-day print for 4 parts and needed to meet a tight deadline. We knew we had zero room for error, so we used our generative design software to rapidly iterate different versions of the part until we reached an ideal design that we were confident would print successfully the first time.

Here’s what you can expect from the generative design process at RE3DTECH:

- Step 1: Discuss part requirements and end-use criteria with the customer.

- Step 2: Enter the part into our generative design software, where we’ll generate design iterations based on part requirements.

- Step 3: Set up a design review with the customer to narrow the designs down to the top 3-5.

- Step 4: Print out 3-5 unique prototypes for physical testing purposes. At this point, we may have an ergonomic design review with the customer to make the parts more aesthetically pleasing or intuitive—especially if we’ll be doing a production run.

- Step 5: Finalize the design and print the parts.

Do you have a part that could benefit from generative design? Send it our way! The team at RE3DTECH is ready and waiting to fulfill your industrial 3D printing needs.