We’re excited to continue this ongoing series on our blog spotlighting some of the best material options for industrial 3D printing. Last month, we told you everything you need to know about 17-4 stainless steel, one of the most commonly used materials for 3D metal printing services.

RE3DTECH Team

Recent Posts

Consolidate Assemblies and Shorten Supply Chains with 3D Printing

It’s no secret that industrial 3D printing provides manufacturers with unparalleled design freedom compared to CNC machining. But in mainstream discussions about the advantages of 3D printing services, there’s one major benefit that tends to get overlooked:

Post-processing services are key to producing high-quality 3D printed parts that have an aesthetically pleasing, finished look. At RE3DTECH, we include these services with every customer order to ensure that the parts we deliver not only function perfectly but also look their very best.

As we continue to expand our capabilities to deliver the most effective 3D printing material choices to our customers, we thought it would be fun to start a new series on this blog spotlighting our materials.

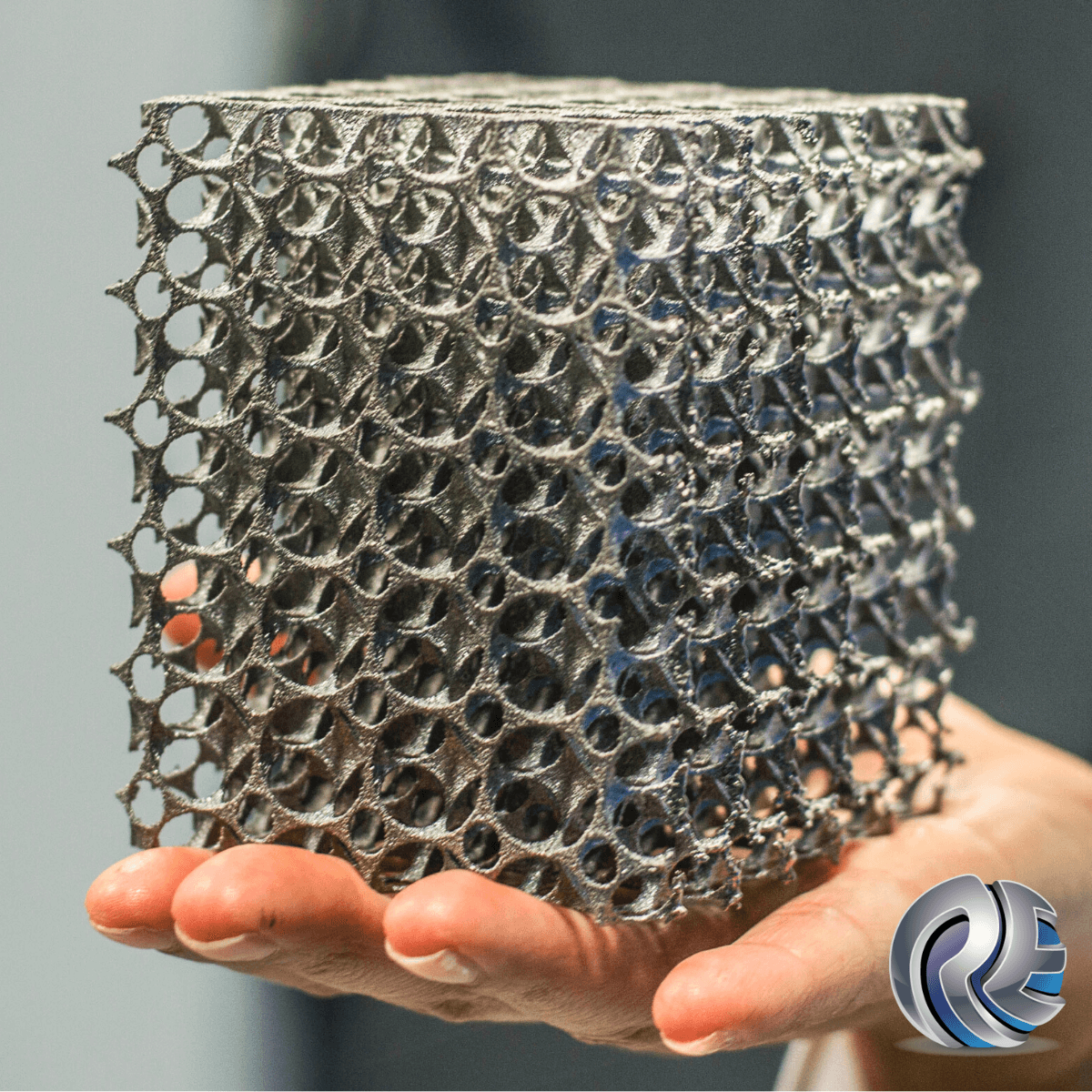

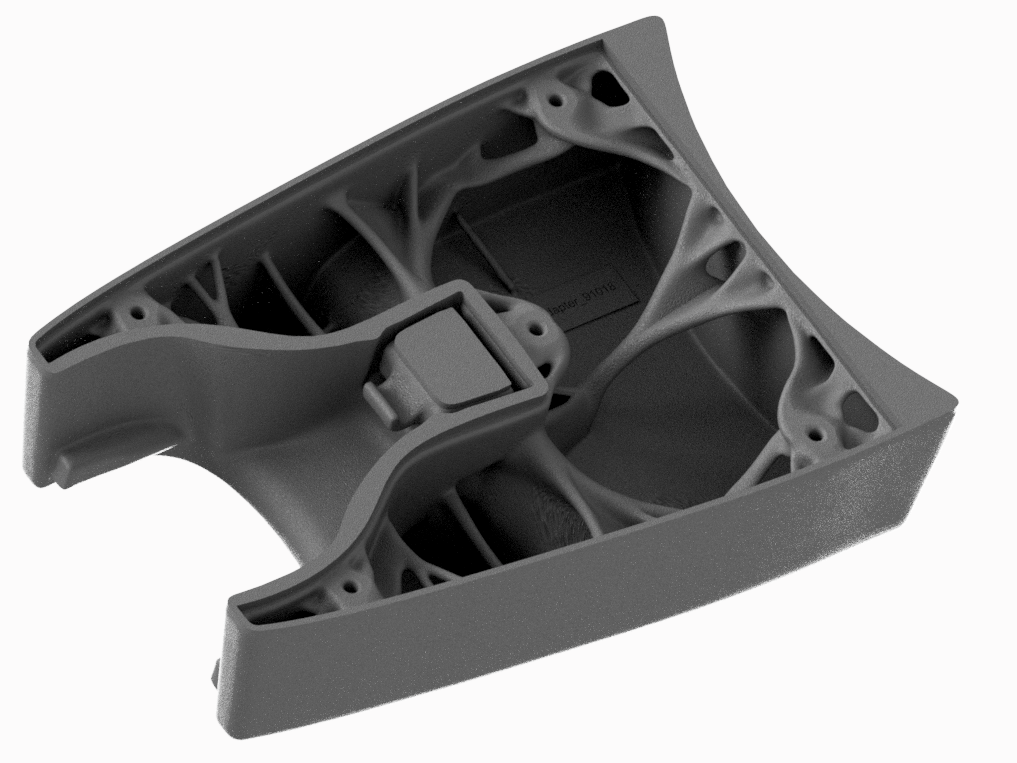

One of the major advantages of industrial 3D printing is the design freedom that it allows. Traditional manufacturing restrictions can hinder creativity and innovation. But additive manufacturing gives engineers the opportunity to create complex features that are difficult or even impossible to machine.

Additive manufacturing is such an emerging market that there’s still a lot of speculation about what it will take for this technology to move beyond traditional prototype applications to an established mainstream production manufacturing solution.

Overview of SLA & DLP Industrial 3D Printing Technology and Materials

As a leader in the additive manufacturing space, RE3DTECH is always looking to add new industrial 3D printing equipment to our growing list of technologies.

Leveraging Generative Design to Produce an Ideal 3D Printed Part

Design forAdditive Manufacturing (DFAM) has many advantages over designing for CNC machining, including opportunities for complex geometries, cost-effective iteration, weight reduction, and more.

How Additive Manufacturing Is Changing Mass Customization

Traditional manufacturing methods like CNC machining and injection molding have long been considered the go-to solutions for mass production. And while these methods are useful for manufacturing large quantities of identical parts, the conventional wisdom doesn’t hold up when mass customization comes into play.

At RE3DTECH, we approach 3D printing a little differently than other 3D printing service bureaus. We’re intent on helping our customers leverage industrial 3D printing for production volumes, so naturally we view the potential for 3D color printing from the lens of production.