As a leader in the additive manufacturing space, RE3DTECH is always looking to add new industrial 3D printing equipment to our growing list of technologies.

We’re in the process of reviewing SLA and DLP 3D printers, and while we haven’t pulled the trigger on a specific printer just yet, we’re already excited about the possibilities on the horizon.

Today, we’re providing an overview of these technologies so our customers can know what to expect in terms of properties, applications, and—perhaps most importantly—materials. Because each time we add a new 3D printing technology, we open the door for a whole new set of materials to work with.

What Is SLA and DLP 3D Printing Technology?

Stereolithography (SLA) and Digital Light Processing (DLP) are the two primary technologies used for resin 3D printing. While there are some differences between these processes—DLP is generally faster and the printers require less maintenance—their essential functionality is very similar.

Liquid resin is exposed to a light source in the form of a projector in the case of DLP or a laser in the case of SLA, and that light source cures the resin as it builds up layer by layer to create a desired shape.

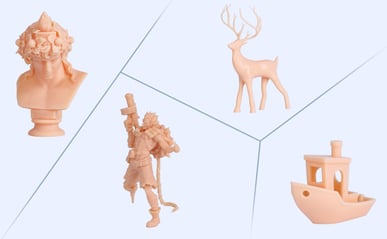

Both SLA and DLP technologies are known for producing finely detailed parts with an extreme degree of accuracy, precision, and quality—plus an exceptionally smooth surface finish.

Many industries and applications leverage SLA and DLP technologies, however they are most ideal for functional prototyping, tooling and fixturing, and dental and jewelry applications that require minute details.

But perhaps the biggest advantage of SLA and DLP technologies is the wide selection of versatile materials compared to other 3D printing technologies.

Top Open Source DLP Materials Available on the Market

Here’s a look at the open source DLP materials we’re most excited about. These materials are typically compatible with SLA technology as well.

- ELEGOO Water Washable 3D Printer Resin. Known for its high precision, fast curing, and excellent stability, this resin is water washable for added convenience. That means no dangerous solvents are required to remove excess resin. It’s perfect for applications ranging from board game miniatures to industrial parts and components.

- Siraya Tech Blu 3D Printer Resin. This tough resin is easy to use and performs extremely well under stress. Balancing strength and hardness, it’s ideal for functional parts that must be both strong and flexible. While other resins are known for being brittle, Blu can withstand drops and other forces without breaking.

- eSUN General Purpose Standard Photopolymer Resin. This general purpose hard resin promises high precision, low shrinkage, and great stability. It cures quickly and has excellence fluidity, ensuring a high successful printing rate.

- AmeraLabs TGM-7 LED Grey. Designed specifically for tabletop gaming miniatures, this fast curing resin is the perfect balance between stiffness, impact resistance, and flexibility. It captures fine details with its hard, non-sticky, and paintable surface.

- Siraya Tech Fast Printer Resin. This general purpose resin is fast to print, fast to cure, and less brittle than other affordable resins. It’s easy to use and strong enough to withstand forces without breaking.

- ANYCUBIC 3D Printer Resin. Offering high precision, quick curing for rapid prototyping, and a notable rigidity and toughness, this resin is great for a variety of applications.

If you think SLA or DLP industrial 3D printing technology could be right for your part, let’s start a conversation. Contact us today to discuss your project!

Image courtesy of ELEGOO