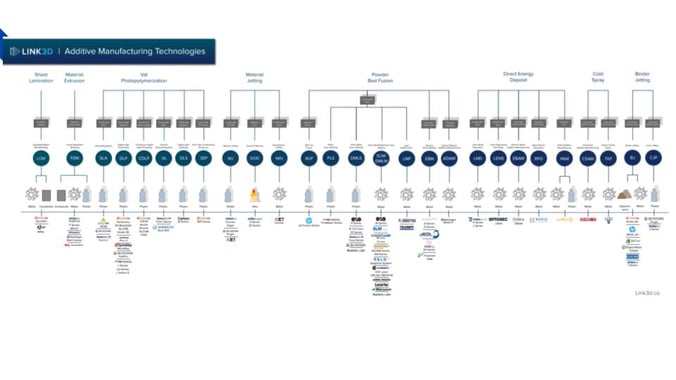

Are you interested in 3D metal printing services but confused by what seems like dozens of different acronyms depicting material types and technologies? You’re certainly not alone!

With so many available options for 3D printing metal parts, engineers often find themselves overwhelmed with decision fatigue trying to make the right choice.But you don’t have to come to these important decisions on your own. When you work with Re3DTech, we’ll guide you through the sea of acronyms, recommending the ideal additive manufacturing technology and material for your specific application.

Additive Manufacturing Technology #1: DMLS

Also known as DMLM (Direct Metal Laser Sintering) or PBML (Powder Bed Metal Laser Fusing), DMLS (Direct Metal Laser Sintering) is the most commonly used and readily available metal 3D printing technology.“Direct metal laser sintering” is ultimately a fancy way of saying that a laser is melting finely powdered metal, hence the overlap in terminology. Next time you see an additive manufacturing technology described as “Powder Bed Fusion,” you’ll know that it’s synonymous with “DMLS” (or vice versa).

Our DMLS metal materials list includes:

- AlSi10Mg (Aluminum): commonly used for functional prototypes, small production runs, and user-specific products requiring a material with good thermal properties and low weight

- 6061 (Aluminum): commonly used for aerospace, automotive, and defense applications requiring a versatile, lightweight material with good corrosion resistance and thermal conductivity

- Ti64 (Titanium): commonly used for aerospace, medical, marine, and chemical applications requiring a high strength, lightweight material with good corrosion resistance

- 17-4 (Stainless Steel): commonly used for pump shafts and mechanical seals requiring a material with high strength and modest corrosion resistance

- 316 L (Stainless Steel): commonly used for aerospace, food processing, pharmaceutical, and marine equipmentapplications including heat exchangers, nuts, bolts, screws, and tubing

- Eos Maraging Steel: commonly used for high-end applications like aerospace or motorsports requiring a tool steel with good mechanical properties

- Cobalt Chrome: commonly used for dental prostheses, model castings, and medical applications

Additive Manufacturing Technology #2: Binder Jetting

Binder Jetting (BJ) is a highly scalable metal 3D printing process that consists of applying a liquid binder to powder particles, bonding those particles layer by layer to form a completed part. It’s a fast, simple, cost-effective technology with the added benefit of preventing residual stress on a part.

We currently have 17-4 PH (Stainless Steel) available for metal Binder Jetting, but soon we’ll be adding 316 L (Stainless Steel), D2 Tool Steel, Ti6AI4V, DM 625 Inconel 625-grade, and DM 247 MAR M247.

Additive Manufacturing Technology #3: Markforged ADAM

Drawing inspiration from MIM (Metal Injection Molding), Markforged extrusion-based ADAM technology melts and extrudes filament from a heated nozzle to the desired 3D geometry. Unlike DMLS and BJ, there are no high-powered lasers or powdered metals, allowing for a safe, reliable, cost-effective 3D metal printing method.Markforged ADAM is Re3DTech’s preferred printing technology, offering many unique advantages such as short lead times, lightweight parts, wide material selection, and low cost per part.

Our Markforged ADAM metal materials list includes:

- Copper: Copper’s high thermal conductivity makes it a good choice for aerospace, automotive, and consumer electronics applications, such as heat sinks and busbars.

- 17-4 PH Stainless Steel: Stainless is a hard, high-strength material with good corrosion resistance. It’s often used in aerospace, medical, and petroleum applications that require these properties.

- Inconel 625: Inconel is a perfect material for harsh environments, including functional prototypes and end-use parts that will be subjected to weatherability or wear and tear.

- D2 Tool Steel: D2 offers abrasion resistance and compressive strength. It’s a common choice for cold work applications that are designed with sharp edges.

- A2 Tool Steel: Similar to D2, A2 tool steel offers high compressive strength and good dimensional stability during hardening and tempering. It’s also a good option for cold work applications that need a hearty material.

- H13 Tool Steel: H13 is a go-to material selection for press brake tooling, dies and punches, high temp tooling and wear resistant inserts.

We’re always expanding our capabilities to deliver the most effective 3D metal printing services to our customers. Even if we don’t have a particular technology in-house (yet!), we work closely with our network of trusted partners to ensure that we’re always offering the best possible solution for a specific part and application.

Don’t let all those confusing acronyms discourage you from 3D metal printing! Request a quote and we’ll help you identify the right technology and material for your next project.

(Image courtesy: LINK3D)

At Re3DTech, we believe that 3D printing will repatriate and revitalize our manufacturing industry – and is the future of American manufacturing! Re3DTech provides 3D printing and contract manufacturing services with a commitment to quality, speed, and customer service. We supply thousands of parts to customers every week in industries including Healthcare, Automotive, and Aerospace. It is our mission to provide a custom solution to our customers’ needs.

Leveraging our production additive manufacturing technologies, we have the in-house expertise and capabilities to help lead your company down the path of additive. Take advantage of the advances in 3D printing to improve your manufacturing - contact us today to see how we can help!