Before getting a part 3D printed, it’s important to have a conversation with your additive manufacturing partner about quality expectations.

Talking Quality Expectations with Your 3D Printing Partner

Is Metal Binder Jetting the Right 3D Metal Printing Technology for Your Part?

A number of innovative technologies are paving the way for 3D metal printing, but none are expected to evolve quite as rapidly in the next few years as binder jetting.

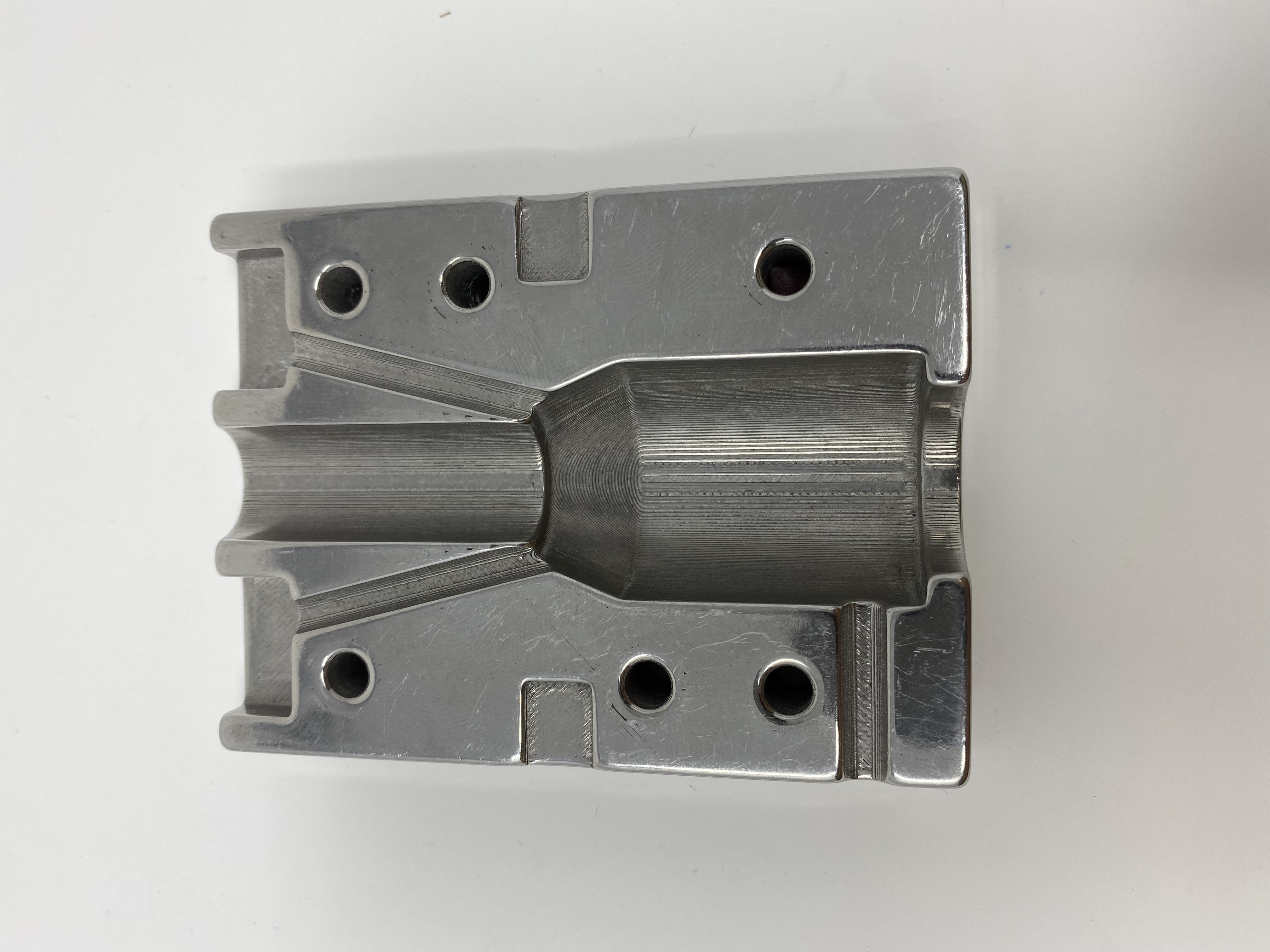

3D Printing Makes Prototype Injection Molding Quick, Cheap, and Easy

When we talk about specializing in prototypes here at RE3DTECH, we’re mostly referring to our ability to 3D print a functioning sample version of a final product.

Industrial 3D Printing Provides Multiple Unique Prototypes During One Design Cycle

If you’ve relied on traditional manufacturing methods like CNC machining for prototypes in the past, you’re probably used to getting 1-2 iterations per design cycle. Since each unique part requires new programming and setup for a machine shop, additional iterations are treated separately and carry additional costs.

Is 3D Printing a Better Fit Than Your Current Manufacturing Process?

Is industrial 3D printing a better fit for your part than your current manufacturing process? It could very well be—you just may not know it yet!

Topics: 3D Printing

Is Bridge Manufacturing with 3D Printing the Right Solution?

At Re3DTech, we’re committed to helping our customers better understand additive manufacturing. We use our LAYER3D blog to peel back the layers of the 3D printing industry and explore all topics relating to this incredible technology.

Topics: 3D Printing, Application, Industry News

Topics: 3D Printing, Application, Industry News

Are you looking for an ISO 9001:2015 certified additive manufacturing company?

At Re3DTech, you can be certain you’re getting 3D printing services from a team of experts committed to providing consistent, high-quality parts!

ISO certification, which establishes a standard criteria for quality management, isn’t always necessary for prototyping and functional testing. But most companies seeking 3D printing services for production orders consider ISO certification a baseline requirement.

When one of our biggest medical industry customers told us they couldn’t qualify us as a supplier until we were ISO certified, we sprang into action. We knew—and they knew—that our parts and processes were already up to ISO standards, so the next step was getting the official certification.

The way we see it, our ISO certification shows customers that quality takes top priority and that we have the processes in place to maintain the highest level of quality for each project.

How ISO Requirements Differ for Additive Manufacturing vs. Subtractive Manufacturing

ISO certification was traditionally associated with subtractive manufacturing. So there has been a bit of a learning curve in defining ISO standards for additive manufacturing companies.

The documentation requirements are comparable for any type of manufacturing. But there’s variance in how parts are qualified, tested, and measured.

With machined parts, for example, there are specific tolerances to measure. But industrial 3D printing technology is capable of producing exceptionally complex geometries. It’s impossible to put a set of calipers on a 3D printed part and measure every dimension effectively. Auditors are still learning what alternative technologies to use for qualifying 3D printed parts.

The Process of Becoming ISO Certified at Re3DTech

We spent nearly two years building an infrastructure that would enable us to scale and standardize our processes. That preparation made it relatively easy for us to become ISO certified when the time came. Becoming ISO certified involved:

- Integrating the software we use for quoting, production, accounting, and other operations

- Building airtight file management systems that track and show we’re always using the most current revisions for production projects

- Implementing training processes to ensure consistency in part production, from cleaning the printers to post-processing the parts to packaging and shipping the orders

- Documenting the processes and operations that occur at each workstation

- Developing quality inspection standards for qualifying parts coming off the printer and deploying corrective action plans as needed

Do you need 3D printing services for prototype or production? Rely on an ISO certified additive manufacturing company like Re3DTech. Request a quote using our secure online form!

Topics: 3D Printing, Application, Industry News

10 Additive Manufacturing Articles You Don’t Want to Miss

At Re3DTech, we’re committed to helping our customers better understand additive manufacturing. We use our LAYER3D blog to peel back the layers of the 3D printing industry and explore all topics relating to this incredible technology.

Topics: 3D Printing, Application, Industry News

Get 3D Printed Composite Parts with Impeccable Surfaces | Re3DTech

It’s no secret that we love Markforged 3D printing technology. Our Markforged 3D printers deliver unparalleled versatility, rigidity, and durability, producing composite parts that are just as strong as metal.

Topics: 3D Printing, Application, Industry News